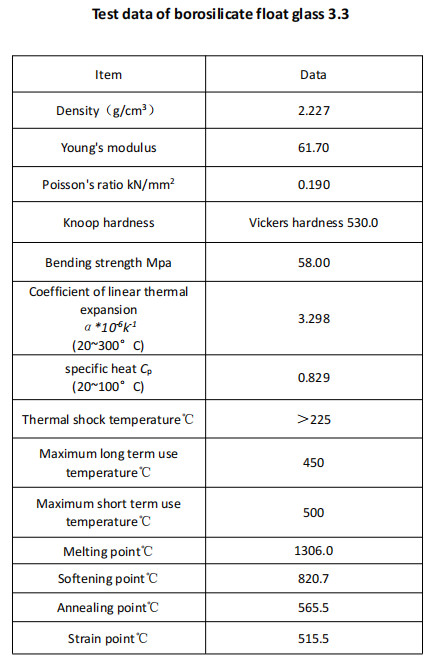

High borosilicate glass 3.3 is a glass with enhanced fire resistance- Oven glass panel

Product Introduction

High borosilicate glass is a glass with enhanced fire resistance. It is not easy to burst under sudden temperature changes of 0-200 degrees. Take the glass panel out of the freezer and immediately fill it with water without frying. Single-layer high borosilicate glass products can be directly put into the oven and can be dry-fired on an open flame for 20 minutes.

Borosilicate glass 3.3 is a type of heat-resistant and lightweight glass that can be used in many different applications, including ovens. The most common borosilicate 3.3 oven glass panel is made from the same material as traditional borosilicate glasses, but it has been specifically designed to withstand temperatures up to 300°C (572°F). This makes it an ideal choice for use in ovens due to its superior resistance to thermal shock and excellent durability over time.

Application field

Borosilicate 3.3 serves as a material of true function and wide applications:

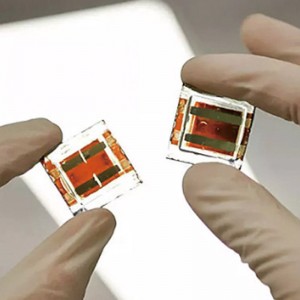

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (lining layer of repellence, autoclave of chemical reaction and safety spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Medical technique and bio-engineering;

Advantages

The main advantages of using borosilicate 3.3 oven glass panels are their strength and versatility compared to traditional glasses like soda lime or tempered laminate safety glasses which cannot resist such high temperatures without cracking or shattering under pressure. Borosilicates also have better chemical resistance than these other types of glass, making them more suitable for use with food products or hazardous materials found in laboratories and industrial settings where the highest level of protection from contact with volatile chemicals is required.

Thickness Processing

The thickness of the glass ranges from 2.0mm to 25mm,

Size: 1150*850 1700*1150 1830*2440 1950*2440

Max.3660*2440mm, Other customized sizes are available.

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc.

Package And Transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Conclusion

The use of Borosilicate 3.3 Oven Glass Panels also helps reduce energy consumption since they don’t need extra insulation layers around them – allowing hot air produced inside the oven itself to circulate freely throughout cooking chambers resulting in faster preheating times , improved baking results , reduced cook times overall – thus saving you money on electricity bills each month!

Furthermore , capable of enduring extreme temperature conditions then investing in a set Borosilicate 3.3 Oven Glass Panels may just be your best option ! Not only do they offer unbeatable resilience against corrosion & heat damage – but their lightweight nature makes them easy install & maintain too !