This Revolutionary Glass Made Of Borosilicate 3.3-Microwave Oven Glass Panel

Product Introduction

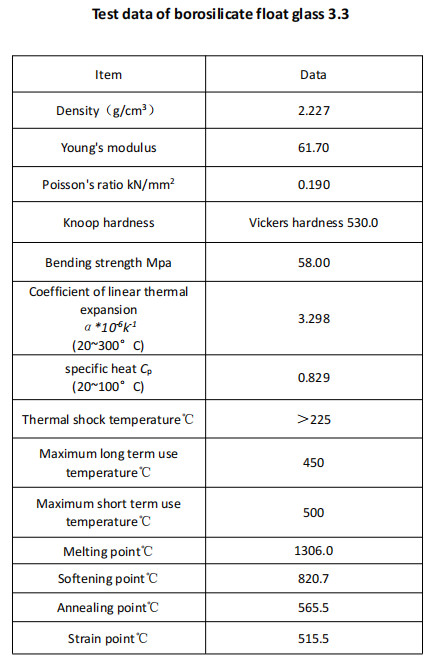

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass. The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components. The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass. The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass. Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

Moreover, the hardness of borosilicate 3.3 heat-resistant glass is 8-10 times that of ordinary glass, and it can also be used as bulletproof glass. Borosilicate 3.3 heat-resistant glass is more resistant to acid, alkali and corrosion, so its service life can reach more than 20 years.

Characteristics

Low thermal expansion (High thermal shock resistance)

Excellent chemical resistance

Outstanding clarity and ruggedness

Low density

Application field

Borosilicate 3.3 serves as a material of true function and wide applications:

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (lining layer of repellence, autoclave of chemical reaction and safety spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

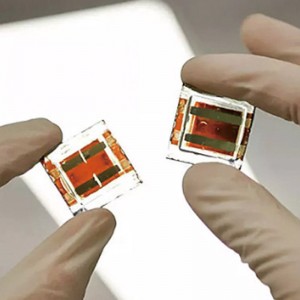

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Medical technique and bio-engineering;

8). Safety protection (bullet proof glass.

Thickness Processing

The thickness of the glass ranges from 2.0mm to 25mm,

Size: 1150*850 1700*1150 1830*2440 1950*2440

Max.3660*2440mm, Other customized sizes are available.

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc.

Package And Transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Conclusion

This revolutionary glass is made of borosilicate, a special material that combines strength and durability with an extraordinarily high heat resistance.

Whether it’s functional or decorative, this magnificent material will make any project look great while helping protect against extreme temperatures up to 500°C (932°F). And because of its excellent thermal shock properties, it won’t cloud over time from frequent temperature fluctuations either!

Our 3.3 borosilicate glass is extremely versatile too – you can use it for almost any purpose imaginable; creating beautiful vases and candle holders; scientific instruments such as microscope slides and petri dishes; kitchenware items like oven-proof baking dishes; art projects like stained-glass windows…the possibilities are endless! Its lightweight yet strong construction allows for easy transport between workspaces so you can take your creations wherever they need to go. And thanks to its crystal clear transparency, light passes through beautifully with no distortion whatsoever – making sure whatever design you come up with looks perfect every time!